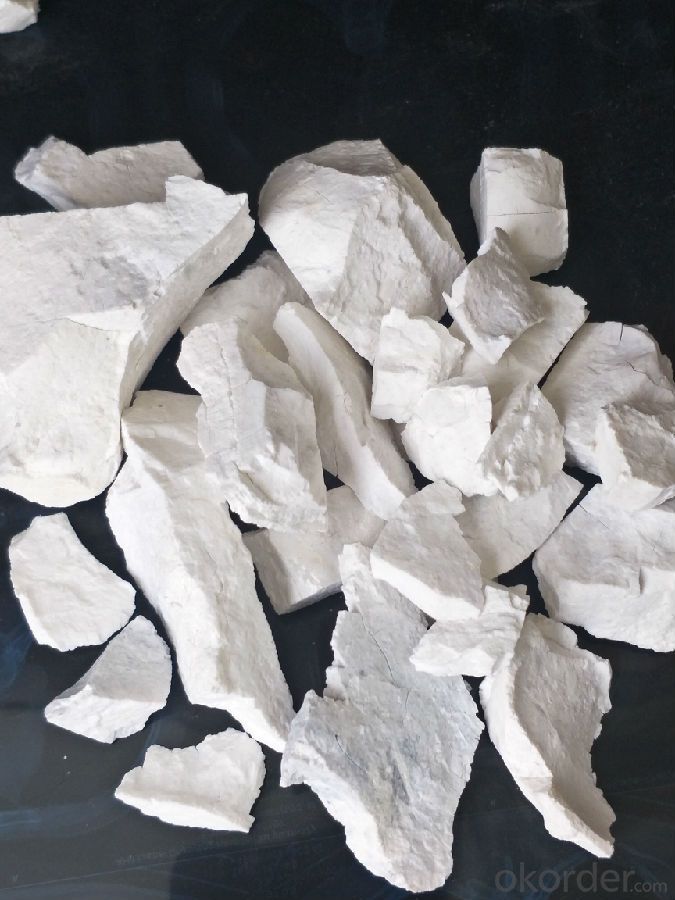

Calcined Kaolin Clay Powders for Refractory Fire Clay Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Product Description

Place of Origin:China

Model Number:Calcined Kaolin

Type:Powder

Technique:Calcined Kaolin

Dimensions:300-5000 mesh

SiO2 Content (%):52±2%

Fe2O3 Content (%):≤0.5%

Al2O3 Content (%):45±2%

Moisture Content (%):≤0.5%

TiO2 Content (%):≤1.5%

K2O Content (%):<0.3%

Application:Refractory

Other Names:Calcined Kaolin

Product name: Kaolin

Payments terms:

1. 100% L/C at sight

2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Advantage: Timely Shipment, High quality, Good performance

Packing: 1mt/bag or as customers' requirements

Size: powder

Sample supply: free sample

Color: white

MOQ: 25Mt

Supply Ability

Supply Ability:300 Metric Ton/Metric Tons per Month

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

- Q:How to divide the fire rating standards of insulation materials?

- The fire rating classification standards of insulation materials, 1. Insulation materials with A-level combustion performance: inorganic fiber spraying, rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. Insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powder particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q:Who knows the new fireproof and thermal inuslation matertial?

- New fireproof and thermal inuslation matertial: foam concrete building blocks brick. The foam concrete building blocks brick is a new fireproof and thermal insulation material, with distinct advantages compared with the organic insulation material . Foam concrete can be used as wall materials, and it has a good self-insulation properties, so there is no problem of dropping off the outer insulating layer. A small part takes external wall exterior insulation, with mostly anchoring or dry hanging, which are not easy to fall off. Very few uses paste. Since the foam concrete and wall materials are of the same nature and strong adhesive, so it is also not easy to fall off.

- Q:How many external wall thermal insulation fireproof material are there

- Class A exterior wall insulation: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic foam, foam glass

- Q:What refractories have good mechanical property resistance and heat expansion and cold contraction property?

- Explain that where you use it for and what requirements you have. Follow-up: I use it in metallurgical furnaces with the features of strong stirring and acidic residue.

- Q:What are refractory materials?

- Refractories can be divided to two categories based on the shape and three categories according to the chemical nature of acidity, neutralily and alkalinity. Alkaline refractory materials are magnesia-carbon brick, magnesia chrome brick, calcium magnesium brick and magnesia-chrome bricks. Neutural refractory mateial are high alumina brick, corundum brick and clay brick. Case-hardened refractory materials are castable, ramming mass, gunning mix, coated mix, dry vibration material, etc.

- Q:What kind of materials can be tested their electrical resistivity in the current refractory industry?

- fused cast bricks, fused zirconia corundum blocks, corundum, high zirconium

- Q:What is the limit of fireproof rolling shutter?

- Fire proof door can be divided into Serie A, B and C in terms of fire endurance limit, fire resisting limit are not should be less than 1.20h, 0.90h and 0.60h. Set firewall has difficult sites can use fire shutter fire partition separating, when the back fire surface temperature rise refractory limit determination conditions of fire shutter, the fire resistant limit not less than 3H; when employed does not include back fire surface temperature rise do fireproof limit determination conditions of fireproof rolling curtain, on both sides of the shutter should be set up a separate closed type automatic water spraying system protection, sprinkler system continuation of time should not be less than three hours.

- Q:What are the best refractory materials in 2,400 Celsius degree?

- and carbon fiber or nanomaterials.

- Q:What are the specifications of fire resistant bag?

- Fire resistant bag is featured by wear resistance, resistance to heat, shock, acid and alkali, somke, fire, bacteria, mould and static electricity. Fire resistant bag is generally used for table top, desktop, wall face, cabinet, office furniture, wall-hung cupboard, etc. The common specifications include: 2135mm×915mm, 2440mm×915mm, 2440mm×1220mm, thickness 0.6-1.2mm. I hope it can help you.

- Q:who knows the technology of fireproofing material?

- 1, dealing mould, scrape and clean the thick liquid on the surface of mould with tin-coated steel scraper blade or plaster tool. 2, adjust laminator, according to the thickness of fireproof?panel, adjust each roller, keep them parallel. 3, ingredient, according to the requirements of recipe, stir the raw materials uniform with agitator. (usually we should add bittern firstly, stir it with modifying agent for 5 minutes, then add filler and stir for 2-3 minutes, finally add grogs and stir it to uniform) note: the stirring speed should be kept in 60-80 r/min. 4, place the cloth, place a layer of non-woven fabric and two layers of glass fiber fabric (mechanical spread fabric). 5, flitch, place the materials after compounding and stirring into stop gauge of laminator, then you can start up and produce continuously, it's finished product after finishing. note: the distance between two templates is 2-4mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Related keywords

You Might Also Like