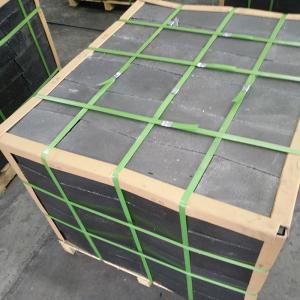

Dolomite Brick magnesia calcium brick for Steel ladle,Aod,VOD

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Product details

Dolomite Brick,magnesia calcium brick used for Steel ladle,Aod,VOD.

Magnesia-Calcium bricks are made of two-step burned magnesia-calcium sands and high pure magnesia. After high pressure shaping, high temperature burning and paraffine vacuum dipping. It has good high temperature creep-resistance and slag resistance. It is the best materials for AOD, VOD,ladle.

Dolomite brick/Mag Calcium Brick Product Data

Type | LKMG15 | LKMG20 | LKMG25 | LKMG30 | LKMG40 | LKMG50 | |

MgO(%) | 80.3 | 76.3 | 70.3 | 66.3 | 56.3 | 43.3 | |

CaO(%) | 17 | 21 | 27 | 31 | 41.0 | 54 | |

Al2O3(%) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

Fe2O3(%) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | |

SiO2(%) | 1.3 | 1.3 | 1.3 | 1.3 | 1.2 | 1.3 | |

Bulk density(Kg/m3) | 3030 | 3030 | 3030 | 3030 | 3000 | 2930 | |

Apparent porosity% | 13 | 12 | 12 | 13 | 13 | 12 | |

Cold Crushing Strength (MPa) | 80 | 90 | 80 | 80 | 80 | 70 | |

Refractoriness Under Load 0.2MPa℃ | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | |

Rupture strength (Mpa) | 2.5-4.5 | 2.5-4.5 | 2.5-4.5 | 2.5-4.5 | 2.5-4.5 | 2.5-4.5 | |

Reheat test,Permanent linear change (%) | – | – 0.35 | – | – 0.61 | – | – | |

Thermal conductivity(W/m.k)-1 | 3~4 | 3~4 | 3~4 | 3~4 | 3~4 | 3~4 | |

Thermal expansion(%) | 800℃ | 0.8~1.0 | 0.8~1.0 | 0.8~1.0 | 0.8~1.0 | 0.8~1.0 | 0.8~1.0 |

1200℃ | 13.5~1.6 | 13.5~1.6 | 13.5~1.6 | 13.5~1.6 | 13.5~1.6 | 13.5~1.6 | |

1200℃ | 1.8~2.0 | 1.8~2.0 | 1.8~2.0 | 1.8~2.0 | 1.8~2.0 | 1.8~2.0 | |

Application of Magnesia Alumina Carbon Brick

Currently dolomite bricks/magnesia calcium brick are used as refractory lining of treatment and casting ladles in many steel plants worldwide. Thanks to its low oxidation potential, does not transfer oxygen to the liquid steel, therefore it makes desulphurization easier, it is highly compatible with basic slag, it increases the yield of Fe-alloys and can grant long service life at optimal refractory costs. The AOD and VOD process are nowadays the most common ways to produce stainless and alloy steel grades. The dolomite and dolo-magnesite refractories are considered as the most common lining for such a metallurgical process, especially for their attitude to desulphurization, to work with silica-based slag and to achieve the best performances in terms of costs and service life. We offers a wide range of fired and C-bond dolomite-based bricks, suitable for many metallurgical treatments.

CNBM International Corporation

We have 13 refractory plants and annual production capacity 500,000 tons, 15 professor level senior engineers,239 engineers,5 senior experts committed Iron & Steel industry.

We produce Magnesia Carbon Brick,Magnesia Brick,High Alumina Brick,Fireclay Brick,Corundum Brick,Corundum-Mullite Brick,Magnesia Chrome Brick,Silica Brick,Silicon Nitride Bonded SiC Brick,Monolithic Refractories.

We have 263 patents, 5 national key new product and 69 provincial and ministerial scientific achievements.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

- Q:The index of magnesia brick

- indexMGe-20 MGe-16 MGe-12 MMGe-8 DBMK-A DBMK-B DBMK-C MgO≥(%) 40 45 55 60 80 80 80 Cr2O3≤(%) 20 16 12 8 6-8 6-8 6-8 SiO2≤(%) --- --- --- --- 2.0 2.5 3.0

- Q:How do you differentiate between the two clearly? Where is the key? Thank you

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q:Brick price?

- There are various series of unshaped refractory gunning, magnesia ramming material, mending material, coating material, dry lining material, composite refining agent, covering agent, tundish and tundish slag wall, ladle drainage sand and electric furnace taphole filler etc..

- Q:High purity magnesia brick masonry mortar for what?

- Always! There is no 800 degrees can be sintered chamotte? As long as the dregs and do not break the aluminum content, the magnesia brick stick together can!

- Q:Magnesia brick

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclase. General can be divided into sintered magnesia brick (also called burnt magnesia brick) and chemically bonded magnesia brick (also known as the two major categories of not burned magnesia brick). Purity and high firing temperature of magnesia, due to the direct contact of periclase grains, known as direct bonded magnesite brick; made of fused magnesia bricks called electrically fused magnesite brick.

- Q:With different capacitance magnesia brick brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius.

- Q:Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- The ore quality requirements of MgO = 41%, CaO = 6%, SiO2 = 5%. The resources of magnesite in China are rich. The types of deposits include sedimentary metamorphic deposits, sedimentary hydrothermal metasomatic deposits and weathering leaching deposits.

- Q:Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q:Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.

- Q:How to identify the fused magnesia brick and sintered magnesia brick

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclase

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

You Might Also Like