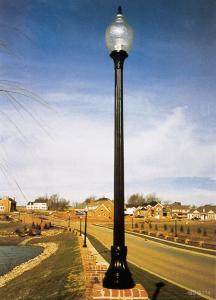

FRP Lighting Pole D25

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Meters m.t.

- Supply Capability:

- 100000Meters m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Specifications of FRP Lighting Pole D25

1) FRP ligthing fiberglass lighting GRP lighting

2) Diameter: 28mm

3) Color: red, black, white, yellow, blue, green, white, gray

4) Length: from 300mm to 7000mm

5) Customer size, color and length are available.

6) High Strength, Corrosion resistance, Chemical resistance, Flexibility, Aging resistance

Introduction of FRP Lighting Pole D25

|

Material |

FRP(Fiberglass Reinforced Plastics) |

|

Shape |

Cylindrical with a slope of 1.8% or 18mm/M |

|

Height |

From 2m to 12m |

|

Type |

Straight pole, single arm, double arm |

|

Gross Weight |

From 10kgs to 150kgs base on pole of weight |

|

Specification refer |

ANSI C136.20-1990, BS EN40, etc |

|

Max Capacity |

1000Pcs/Month |

|

Application |

Especially suitable to be used under extreme weather condition including high humidity coastal area, desert, oil field, high altitude and industrial area with acid and alkali condition |

|

MOQ |

NO MOQ, But advice full container, wwe can count the Q’ty/container based on Client request pole height |

|

Withstand wind speed |

60m/sec (equivalent to Beaufort's Wind Scale 17). |

|

Characteristic |

Anti-corrosion, rust free, Anti UV, Non-conductive and excellent insulation |

|

Price validity |

Offer valid in a month |

|

Lead time |

around 15-60 days |

|

We can supply all kinds of colors. | |

Packaging & Delivery of FRP Lighting Pole D25

| Packaging Detail: | Bubble wrap |

| Delivery Detail: | 15-60days |

- Q:There is a high voltage line above the street lamp. In this case, should the lighting of the street lamp be grounded with each pole? If necessary, how many sets of grounding electrodes should be set?

- The high-pressure line is very easy to lead the thunder, each lampposts must do ground handling, power controller to do lightning protection in accordance with the corresponding grounding, how much to see the root soil resistivity field, to measure ground resistance meter.

- Q:How many kinds of aluminum alloy lamp posts are there? Customers should be about 8 meters or so

- Advantages of aluminium alloy lamp posts:1, good corrosion resistance.2, maintenance free.3, light weight, convenient transportation and installation.4, surface treatment of rich.5, than the iron pole and glass steel pole long life.

- Q:How are fiber glass steel poles made?

- The glass steel production of domestic professional manufacturers is not too much, there are two: Nantong Nantong composite materials Co., Ltd. win-win Jiuding new materials Limited by Share Ltd, the two were used to produce different products have different features of technology.

- Q:What is the material of the street lamp shell?

- Street lamps, lamps that provide lighting for the road, generally refer to lamps within the range of road lighting. A summer Zhixu "fragments of memories": "Pedestrian Street has been scarce and dim."

- Q:What material does the street lamp cover have?

- Many materials, it is best to use double deck, bearing cap with ductile iron, resistant to rolling, sub cover with glass fiber reinforced plastic, waterproof, anti leakage, safe use of Xin Niu covers

- Q:The telescopic pole do simple iodine tungsten lamp, the best

- Advantages and disadvantages of cement lamp holderThe advantages of the cement lamp post: 1., the plug-in type installation can be adopted; 2., the strength is good; 3., no spraying.Disadvantages of cement lamppost: 1. very heavy, bring costly transportation cost; 2. no recycling value; 3. installation equipment is expensive and installation difficult; 4. is more dangerous than other materials.

- Q:What are the proposals for the rationalization of street lighting maintenance?

- Wipe the bulb,The resin is filled with voids between fibers, and the fibers are bonded together to make it a whole. Therefore, the effect of the anti-seepage is mainly borne by the resin. In order to form a compact glass fiber reinforced plastic lining, this paper uses the same resin with the simplified lining as the impervious layer at the joint, and the reinforcing layer adopts the same resin as the winding layer of the tank. Some proper toughening agents and solvents were added into epoxy resin to reduce the viscosity and improve the toughness of frp. In addition, the head and the tank should be cleaned before jointing, joints, including socket, socket and coated glass steel, dry grinding and rough. Before scraping, daub and coating, you should swab the work surface with cotton wool and acetone. On the one hand, it is to remove the grease and paraffin on the inner surface of the glass fiber reinforced plastic lining, on the other hand, it can activate the surface of the glass fiber reinforced plastic, so as to improve the bonding strength. When grinding, be careful not to miss. The quality of the surface treatment is related to the bonding effect between the glass fiber reinforced plastic layer and the tank body. Poor handling often results in cracking, resulting in leakage, so be sure to study the process here

- Q:6 meters Road pole installation should pay attention to what?

- More than 1.5 meters high, you must use seat belts, or take other reliable safety measures.

- Q:White glass fibre reinforced plastic street lamp pole

- Used in Shanghai Baoshan iron and steel works, the quality of low carbon steel, containing less than 0.04% silicon, a bending, die-casting, molding, linear error is almost zero. Design according to level 11 wind resistant requirement, also can resist the earthquake within 8 class at the same time.

- Q:Is there a standard for the upper and lower caliber of the 8 meter street lamp post?

- Depending on how many poles are carrying, only the road lamp holder can be thinner, and the solar panels are thicker. Besides, the thickness of the arm is very large

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 3,000,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Similar products

New products

Hot products

Hot Searches

Related keywords

You Might Also Like