Glass Wool Insulation Fiberglass Insulation Blanket Manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 100000000000 m²/month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Glass Wool Insulation Manufacturers Glass wool

1.Structure of Glass Wool Insulation Manufacturers Glass wool:

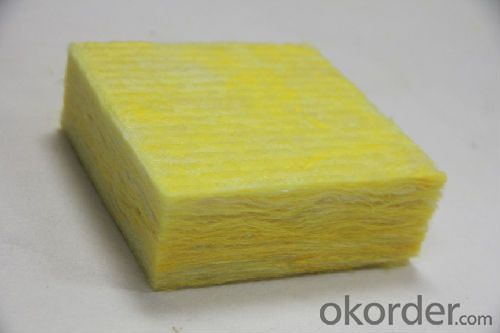

Glass wool with Facing is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. Glass wool is 100% recyclable. It is manufactured from sand and recycled glass(up tp 80% cullet) and offers a very positive environmental balance sheet. It protects the environment, from the beginning to the end of its life cycle and gives more comfort and savings to the occupants of the buildings it insulates.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

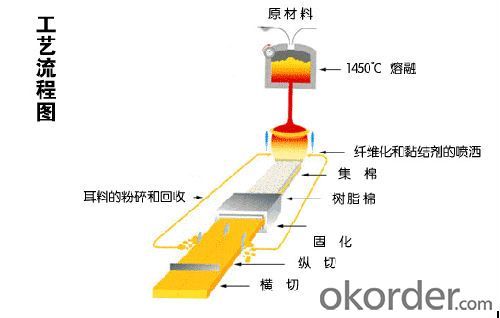

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

2.Main Features of Glass Wool Insulation Manufacturers Glass wool:

The glass wool Blanket with Facing is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

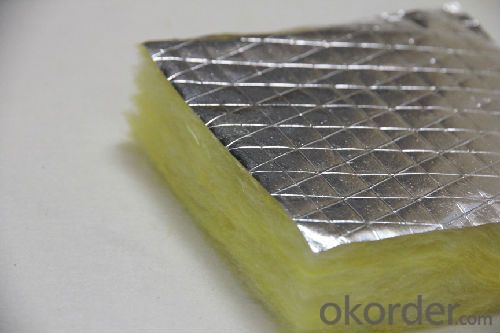

3. Glass Wool Insulation Manufacturers Glass wool Images

4. Glass Wool Insulation Manufacturers Glass wool Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool Blanket with Facing surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

The glass wool product is placed in the glass of meltdown appearance proceed the fiber turn and spray the resin of solid that draw the hot silk wadding form material, then turn through hot solid the deep processing handles and can also make into the series and various products. Our glass wool felt is divided into bare felt and veneer rolled felt, which can effectively resist moisture, sound absorption, corrosion, and aesthetics. The surface layer is added to increase the product's breaking resistance, breakdown resistance, high tensile strength, beautiful appearance and simple construction.

- Q:nan

- Rock wool and glass wool belong to Class A fireproofing rating, secondly, rock wool can endure high temperature of 800 degrees, glass wool high temperature of 450 degrees, again,unit weight of rock wool is relatively heavier and unit weight of glass wool is lighter, finally, glass wool has better waterproof performance.

- Q:nan

- I own a glass wool plant and you can contact me if you need something.

- Q:nan

- Insulated wool is good. Rock wool: It is also known as rock cotton, which belongs to mineral wool. It is a fluffy, short and fine fiber made up raw materials like natural rocks and minerals. Rock wool, whose main raw material are natural rocks like basalt, gabbro, dolomite, iron ore, bauxite and more, is an inorganic fiber made by melting at high temperatures and fibering. Rock wool can serve as the insulation material with ablation resistance and high temperature resistance, the sound-absorbing material and insulation material of buildings and equipment, and the reinforcing material of cement product and rubber for sustituting natural asbestos, and high temperature sealing material, high-temperature filtering material and high-temperature catalyst carrier. 1. Insulation properties: Good thermal insulation is the basic property of rock wool and mineral cotton products. 2. Combustion performance. 3. Sound insulation performance: Rock wool and mineral cotton products have excellent sound insulation and sound absorption performance.

- Q:nan

- Centrifugal glass wool board is board product with a certain intensity which is made by curing centrifugal glass wool. Whether in high or low temperature environment, it can maintain good heat insulation and sound absorption properties, mainly used for interior wall compartment in advanced architecture, compartment, ceiling, heat conservation for iron sheet air duct or aie bellow, sound absorption and noise reduction for studio, machine room and other places.

- Q:nan

- They are not the same material, mineral wool is made by natural mining, rock wool is made by processing a kind of rock, and glass wool is made by processing glass.

- Q:nan

- Which Gree factory do you work for? I work for the third factory.

- Q:nan

- Glass wool belongs to one of the glass fiber categories, which is a kind of man-made inorganic fiber. The sieve plate can not be replaced by glass fiber, which is a kind of elastic felty body produced by glass fiber whose diameter is only a few microns. Glass wool is a product made by fibering the molten glass and adding environmentally friendly recipe binder which is mainly thermosetting resin, use glass wool

- Q:nan

- You can disinguish from appearance. Glass wool is pure white, soft and formaldehyde-free. Formaldehyde-free environmental friendly glass wool is made by bonding, solidifying and moulding previous wool and new binder, based on traditional centrifugal glass wool, through readjustment of formula and molding process of glass wool raw material.

- Q:nan

- Glass wool is made by natural minerals such as quartz, dolomite, feldspar, limestone coupled with soda ash, borax and other auxiliary materials ... Quartz wool is generally placed inside a quartz reactor tube, serving as the filler with high temperature resistance and corrosion resistance.

- Q:nan

- Ask the dealer for product descriptions, and you can search its specifications and parameters and then design based on the performance specifications of specific products. I suggest you first determine which brand of thermal insulation cotton to use, or check if the number is in the tolerance range of national standards of the manufacturers, of course, it is a relatively wide range. I recommend Owens Corning ultrafine glass fiber insulation cotton.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Hot Searches

Related keywords

You Might Also Like