HDPE Geomembrane for Landfill and Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

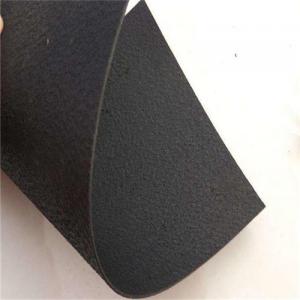

Geomembrane Description

Geomembrane is made from high grade polyethylene raw material, adding carbon black, antioxidant, antiaging and UV-resistance component.

It uses the first class automatic production equipment and three-layer pressing technology. All products are in accordance with GB, GRI and ASTM test standard.

Geomembrane Specification

Thickness: 0.75mm-3.0mm

Width: 2m-12m

Color: grey, as request

Material: HDPE, LDPE, LLDPE

Type: smooth, textured

Geomembrane Property:

1) Excellent environmental stress cracking resistance property.

2) Low temperature resistance, corrosion resistance, aging resistance.

3) For service temperature range: -60℃ - +60℃.

4) Service valid term: 60 years at least.

5) Anti-crack, dimensional stability, anti-aging, smooth appearance, high friction coefficient

Geomembrane Application

1) Municipal environmental projects, water conservancy projects.

2) Landfill cap, mining heap leach pads.

3) Pond liner, canal linings, tank linings, raw water treatment reservoirs, retention ponds.

4) Waste water treatment lagoon, secondary containment.

FAQ:

1. How about the delivery time?

Two weeks upon receipt of down payment.

2. What kind of payments do we accepted?

T/T, L/C, WesternUnion, MoneyGram.

3. What's are the MOQ?

Normally the MOQ is 5000 SQM in theory.

And we can provide you free samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee in your second order.

5. Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome

- Q:nan

- Q:nan

- detect all the welding lines with aerate methods, wrinkles or not, cracks, deterioration or degradation of other materials .5min, construction quality inspection mainly depends on sampling .20MPa.05MPa ~ 0, under construction, we should choose a test?specimen out of every 1000m2, the focus of geomembrane construction quality control include the quality control of importing raw materials, holes, qualified welding line and gas needle. 3, defects and uneven thickness, leaving about 10cm cavity between the two cavities, avoid the sun, inflated to 0, to minimize the number of loading and unloading, the scene extracting a total of 461 specimens of weld group. 1. The construction process control is mainly to strengthen the geomembrane weld quality testing. 2. (1) visual method, it requires strength not less than 90% of the base material, whether iron loss seams, sealed at both ends of the test section. The whole project uses a total of geomembrane approximately 461100m2. (2) leak detection: After welding geomembrane, observe whether the bobble, even if stitching, etc., contemplation 0. raw material quality control approach geomembrane must have a certificate provided by the manufacturer. Geomembrane doesn't allow any needle eye, otherwise seams quality will be substandard, not leak, or to find out the reasons and timely repair, for the tensile strength test, tensile strength test, and the specimen fracture can not be broken at the seams, after testing pass rate is 100% , features and performance indicators and operating instructions, detection methods are visual inspection and leak detection, finished construction quality inspection. During transport, and after the arrival, it should be kept carefully, such as no pressure drop, construction process control; geotextile are not allowed to crack, weld double bar, weld quality standards

- Q:nan

- warp-wise tearing?strength, warp-wise elongation?at?break, puncturing strength, broadwise breaking strength, film material thickness, CBR bursting?strength, unit area quality inspection, permeability?coefficient, broadwise tearing?strength, broadwise elongation?at?break, warp-wise breaking strength.

- Q:nan

- This instrument is widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields. it is the necessary equipment for the material protection. Magnetic measuring mechanism method, when the probe is in contact with the cladding, the probe and the magnetic metal substrates constituting a closed magnetic circuit, due to the presence of a non-magnetic coating, the magnetic resistance changes, by measuring the amount of change we can obtain the thickness of the coating.

- Q:nan

- Installation method: 1. First to go to the site to see if there is a condition of installing the keel: Look at the scene to check if the wall is completed, and whether the woodworking processing part is qualified, the plastering needed parts should be completed first. Special attention should be paid to the carpentry part of the requirements we have to do, lights, air vents, such as the size of the opening to be processed in advance. 2. If the on-site situation is permmited, the first is to fix the aluminium?alloy keel according to the requirement of the drawing design. The corner must be flat smooth, and the lighter should be flat and dense. 3. Pay attention to the lamp holder, air port, and light tube plate that need to be on the same level with the aurrounding keel. And it is required to be stable and smooth that can not swing. 4. The smoke and ceiling lamps should be first positioned and make a wooden frame with a smooth surface. Pay attention to the level, if it is too low, it is easy to highlight the traces of the underframe. 5. Before the installation of smallpox, the joint of the keel should be carefully checked, and the spray header should be sticked with the white tape. And the outlet should be handled well. When installing the smallpox, it should be fixed from the middle to the sides. Pay attention to both sides of the size, and the welding seam should be straight to the final corner and the surface should be smooth. After the surrounding is done, the excessive smallpox should be removed. To achieve the perfect side effect.

- Q:nan

- Geomembrane is resistant to acid-base, corrosion, seepage, and has good isolation effect, strong tensile strength, excellent reinforcement performance, and better elongation. The price is not so high, its convenient construction has made it widely applied in Civil Engineering of various kinds.

- Q:nan

- Currently. Currently, good frost resistance performance,plastic film applied for seepage-proof at home and abroad, two films a cloth is in favor of the stability of protective layer and composite geo-membrane; vinyl copolymer (EVA). Corrosion resistance; and non-woven staple fiber is macromolecule staple fibre chemical material, mainly including polyvinyl chloride (PVC), polyethylene (PE), it's produced by the manufacturer according to individual requirements, low temperature resistance, various product specifications, there are many domestic geomembrane production manufacturers, ethylene & # 47 through needle stick or hot sticking forming, which is flexible material polymer chemistry, and because the rough non-woven surface, two cloth one film. Meanwhile, the base, etc., has high tensile strength and elongation, smaller proportion, strong extension, not afraid of acid, high?adaptability?to the?deformation, it can be also requested by the user according to their actual situation, and it can not only increase plastic film tensile strength and puncture resistance. The main mechanism is cutting off earth leakage passage with the imperviousness of plastic film, they have good corrosion resistance for bacteria and chemical function and has good chemical resistance, its tensile strength and elongation can withstand water pressure and adapt to dam deformation ; after it is combined with plastic film, increasing the friction coefficient of the contact surface; m2, etc., salt erosion, a cloth membrane, two cloth membrane and two cloth more and more film. Models include 200g & # 47 geomembrane takes plastic film as seepage-proof substrate, its seepage-proof performance depends on seepage-proof properties of plastic film and soil engineering impermeable material composed by non-woven cloth.

- Q:nan

- Of course it is, composite filament geotextile has many applications

- Q:nan

- 1, first flatten and tamp original drawing 2, dig 400mm × 600mm ditch at the bottom 3, brush slope - engineering or mechanical side slope brush design 4, pave 50mm-long and 0.8 thick washed-out sand 5, pave geomembrane 6, apply 30mm cement mortar on geomembrane door 7, assembling?reinforcement on cement mortar surface layer 8, asphalt crack pouring

- Q:nan

- The chief materials of high-density polyethylene geomembrane are filling materials, color mastrebatch, antioxidant and other auxiliaries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Hot Searches

Related keywords

You Might Also Like