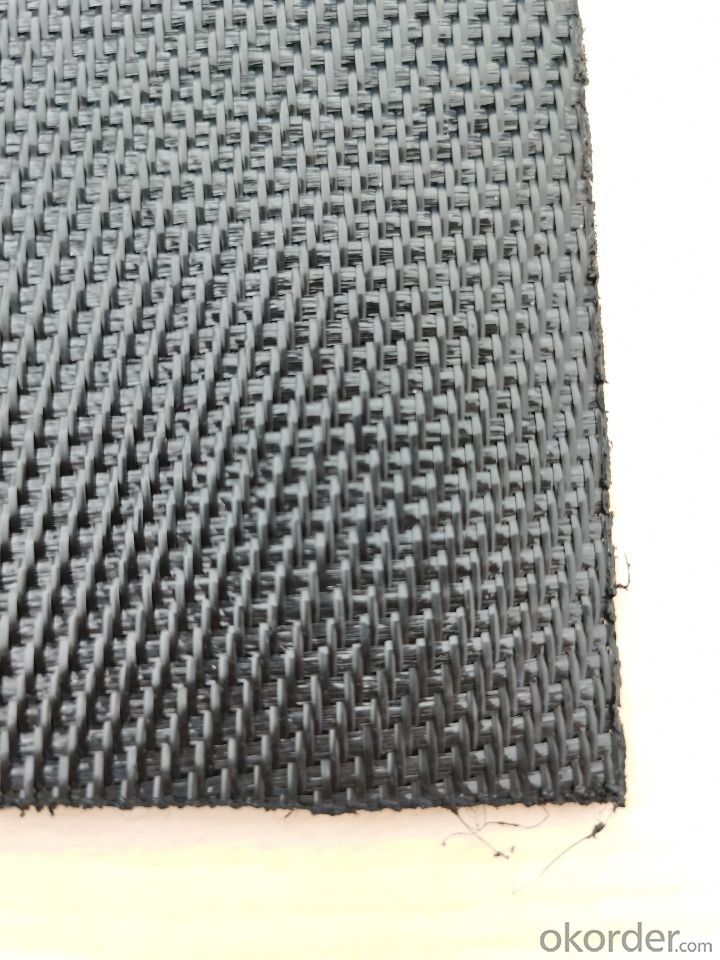

High Strength Woven Geotextile for Road Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 200000 m²/month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

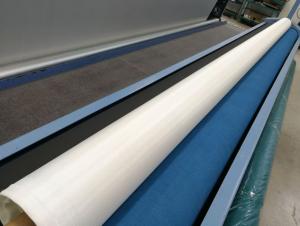

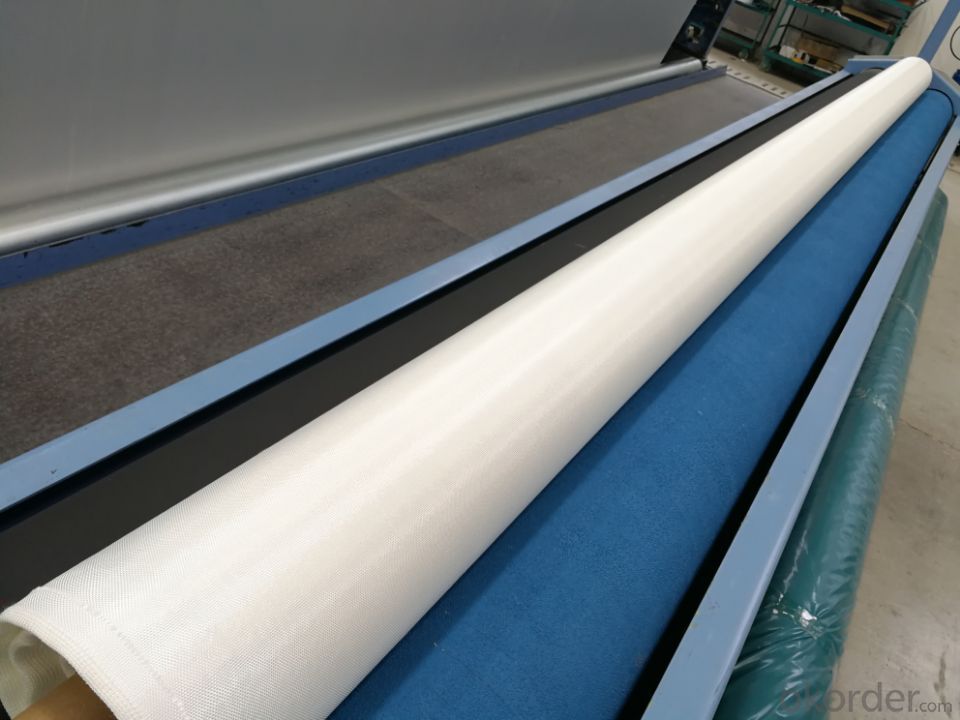

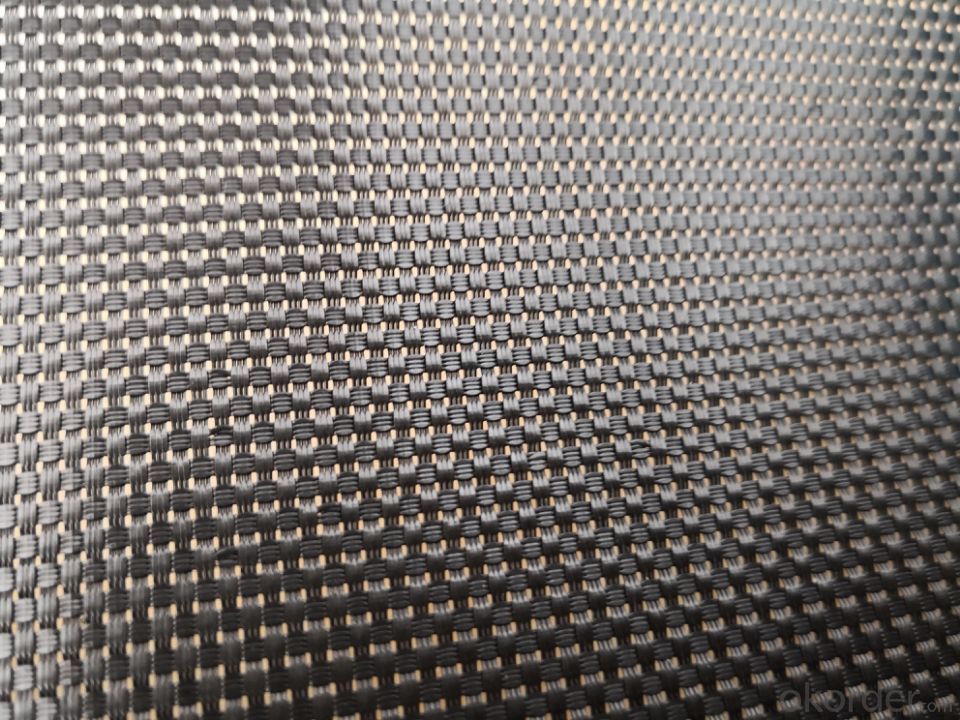

High Strength PP Woven Geotextile

1. Description of High Strength PP Woven Geotextile

CMAX polypropylene woven geotextile is made from polypropylene flit yarn on circle weave machine, including circular loom and flat loom.

2. Specification of High Strength PP Woven Geotextile

Weight: 90gsm – 400gsm;

Width: 1m – 6m; Length: as clients’ required.

3. Technical Data Sheet of High Strength PP Woven Geotextile

Item | Unit | Index | ||||||

Unit Weight | g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Breaking Strength in MD | KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Breaking Strength in CD | KN/m | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation Rate | % | 25 | ||||||

Trapezoidal Tearing Strength | KN | 0.2 | 0.27 | 0.34 | 0.41 | 0.48 | 0.6 | 0.72 |

CBR Mullen Burst Strength | KN | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical Permeability | Cm/s | 10^-1 ~10^-4 | ||||||

Sieve Size O90(O95) | Mm | 0.07 ~ 0.50 | ||||||

Variation | % | ±10 | ||||||

4. Property of High Strength PP Woven Geotextile:

1).Light weight, high strength, low elongation, easy to construct.

2).Reinforcement, separation, drainage and filtration, fencing function.

5. Application of High Strength PP Woven Geotextile

Railways, highways, sport fields, earthwork projects, tunnels, coal mines, walls and slopes, environmental protection and so on.

.

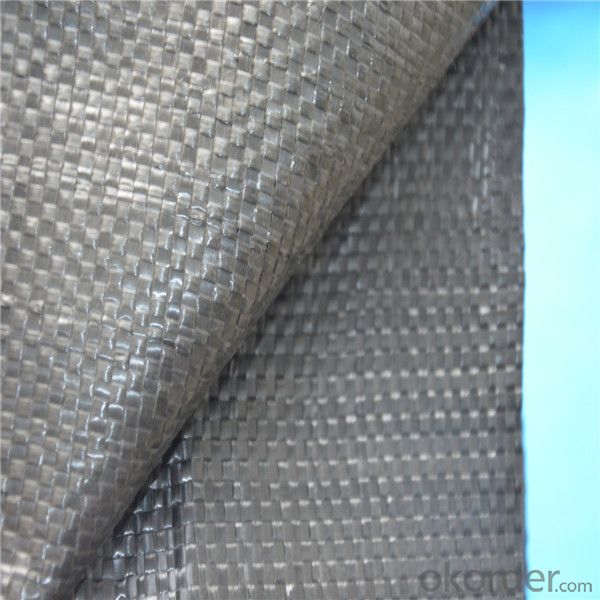

High Strength PET Woven Geotextile

1. Description of PET Woven Geotextile

CMAX filament woven geotextile is made from polypropylene, high strength industrial synthetic fiber as the raw material, made through weaving technology.

2. Specification of PET Woven Geotextile

Breaking strength in MD(KN/m): 35, 50, 65, 80, 100, 120, 140, 160, 180, 200, 250;

Width: 1m – 6m.

3. Technical Data Sheet of PET Woven Geotextile

Item | Specification | ||||||||||

Material | Polyester | ||||||||||

MD(KN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

CD(KN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

Elongation at Break | MD=35; CD=30 | ||||||||||

Width Variation, % | ±0.1 | ||||||||||

CBR Mullen Burst Strength, KN | 2.0 | 4.0 | 6.0 | 8.0 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 |

Sieve Size O90(O95) mm | 0.07 ~ 0.50 | ||||||||||

Tearing Strength, KN | 0.5 | 00.8 | 1.1 | 1.3 | 1.5 | 1.7 | 1.9 | 2.1 | 2.3 | 2.5 | 3.0 |

Weight, g/m2 | 140 | 2200 | 260 | 320 | 390 | 450 | 530 | 600 | 680 | 760 | 950 |

Property of PET Woven Geotextile:

1) High strength, low deformation.

2) Durability: steady property, not easy to resolved, air slaked and can keep the original property long term.

3) Anti-erosion: anti-acid, anti-alkali, resists insects and mould.

4) Permeability: could control the sieve size to retain certain permeability.

Application of PET Woven Geotextile

It is widely used in river, coast, harbor, highway,railway, wharf, tunnel, bridge and other geotechnical engineering.

It could meet all kinds of geotechnical projects needs such as filtration, separation, reinforcement, protection and so on.

FAQ:

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

A: Normally, 5000 m2 per order.

Q: What is your delivery time? Can we short it in 7 days or less?

A: 7 days for sample, 20-25 days for mass production.

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q:Brief description of the application range of Portland cement, ordinary cement, slag cement, volcanic ash cement and fly ash cement

- The three cement strength grades are - the same, with 27.5, 32.5, 42.5, 42.5R, 52.5, 52.5R, 62.5R seven strength levels.

- Q:What are the civil engineering materials?

- Cement: general portland cement, ordinary portland cement, a large number of mixed materials, Portland cement

- Q:Help students learn sister, civil engineering materials

- Non-mechanical hard cementing materials: lime, gypsum, water glass, magnesia cementitious materials

- Q:What are the civil works?

- Mainly engineering construction, measurement, budget, CAD and so on

- Q:Detailed classification of civil works?

- According to its use: can be divided into structural materials, decorative materials, waterproof materials, insulation materials, etc .; according to its function: can be divided into structural materials, decorative materials, waterproof materials,

- Q:Why civil engineering materials are important

- Civil engineering materials are important

- Q:Civil engineering materials (building materials) which is the direction of civil engineering ah? structure? Geology Or what?

- The so-called large civil. Refers to all water, soil, culture-related infrastructure planning, construction and maintenance. At present, the general civil works include roads, water services, drainage services, flood control works and transportation. In the past, all non-military civilian projects were classified into this class. However, as engineering science became more and more extensive, many of the original contents of civil engineering had become independent.

- Q:What are the structural forms of common buildings?

- 1) brick and concrete structure: brick or load-bearing block masonry load-bearing walls, cast-in-place or prefabricated reinforced concrete floor composition of the building structure. Used to build low-rise or multi-storey residential buildings. (2) frame structure: composed of beams and columns of the main skeleton bearing structure, the floor is generally cast-in-place concrete, wall for the filling wall. Used to build high-rise and high-rise buildings. search for

- Q:Discussion on the importance of materials in civil engineering

- On the structure, the construction, the project quality have an impact

- Q:A project with autoclaved aerated concrete block masonry facade, the autoclaved aerated concrete block after a week after the masonry, the project completed a month later, the wall cracks, try to analyze the reasons and put forward solution.

- Autoclaved aerated concrete block is characterized by a large drying shrinkage, the kettle after a week that is masonry, is not completely dry caused by shrinkage cracking.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

You Might Also Like