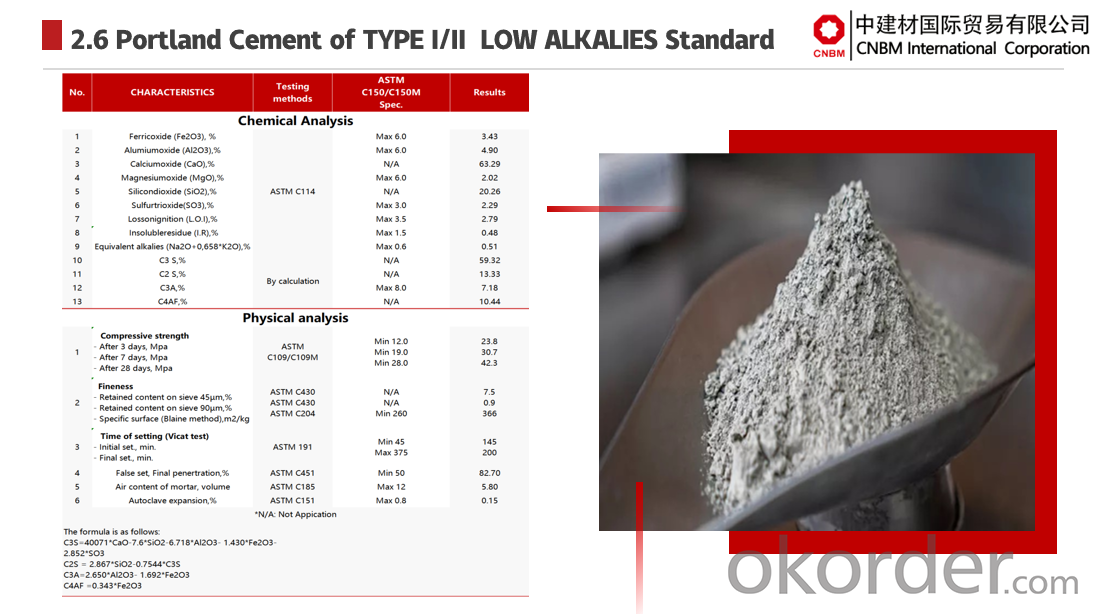

Highest quality for Portland cement of TYPE I/II LOW ALKALIES Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q:When installing cement backer board, is it necessary to put down some thin set mortar and then lay the board and screw in place, or can I do without the thin set?

- You do not need thin set. Just screw it in place.

- Q:how to break a cement wall with fist?

- Take a running start, 50 feet back from wall, run as fast as you can, hold your arm straight and stiff at less than 25 feet, make a fist with your hand at 20 feet or less, at 10 feet or less think of why are you doing this, close your eyes at 5 feet, and Yell out a grunt, it will be more funny to the neighbors. Good luck!

- Q:what are cement,sand and stone quantities in a concrete mix of 1:2:4

- normal mix is as simple as 1-2-3 1 part cement 2 parts sand 3 parts aggregate, [stone] to make it stronger add 1 more part cement

- Q:As in many modern houses, our en-suite shower is made up of tiles fixed onto plaster board. Over the years this has started to leak as the grouting failed, and the plaster board has become soggy and needs replacing. We have had two suggestions from different builders. One suggests ripping out the old plaster board and replacing it with quot;cement boardquot; onto which tiles would be stuck. The other suggestion involves cutting out the old plaster board, replacing it with new plaster board which would then be quot;sealedquot; before tiles are stuck onto it. Does anyone know which of these would be the better option please? Costs of both proposals appear to be similar so we really want the better engineering solution.

- I am no expert other than the re-muddling I have done around my own home, but I would say that the cement board route would be the better way to go. No matter how well sealed the plaster board is, it will eventually draw moisture due to the constant exposure over the years. Before the plaster board is installed, the shower pan should be installed. The plaster board is then installed to sit just off the lip on the inside of the shower pan but not above the edge of the pan. When they install the cement board (which, by the way, is used as exterior siding on homes in the south) make sure they tape and seal all the joints, a process similiar to installing wallboard, but done with a mesh tape and mortar, instead. A reputable drywaller or tiler should know to do this, but I would make sure ... this is no time for misunderstandings. Water damage inside a house can cause a multitude of problems, not the least of which is the shower coming through the downstairs ceiling one night when the boss is over for dinner.

- Q:why cement board over hardie backer board when laying down a counter top for kitchen sink?

- You don't. You use cement board (Durock) over 3/4 plywood if doing a tile top. There is no reason to use hardiboard under Durock. Hope this helps.

- Q:What is the professional terminology?

- concrete. cement is just the stuff that bonds the concrete.

- Q:Describe how concrete is made from cement?

- Concrete contains: * Portland Cement - Sintered limestone, clay, and gypsum * Aggregate - filler such as rocks and sand * Additives - often nylon fibers, or chemicals, to affect strength or cure time * Reinforcement - optional, steel cable, wire, mesh, or bars. * Water - which binds the cement molecules chemically * Carbon dioxide - joins in from the air to help form crystals in the mixture. Concrete is made by: * Preparing the mold or form, such as laying boards, flattening soil, stamping a shape into sheet metal, or just digging a round hole. * Laying the reinforcements, such as a grid of textured steel bar, or maybe nothing at all. * Mixing the rest of the ingredients in a hopper large enough to handle the weight * Pouring the mud/slurry into the form * Packing, shoveling, or vibrating to help settle the mud and remove trapped air. Typical concrete may set (harden) in 30 minutes to a few hours. Cure time is longer (maximum strength) and typically takes from a few days to a month. Cure may be incomplete if the cement is allowed to dry out, so it's common to cover concrete with plastic, sealants, sprinklers, or use chemicals mixed in to help retain moisture during the cure. These same procedures happen, whether it's a bag of quick-crete poured into a hole with a mailbox post, or whether it's a million ton footing poured in a single session. A great way to see this in action is to look for road construction, or bridge construction.

- Q:I just poured cement anchors for a swingset. Eventually, I will cover the entire area with a tarp and then 3-4 inches of pea gravel. I'm wondering how long I should wait, to do this. Should I wait a week or so for the cement to cure more, before I cover it up? Or can I lay down the tarp immediately?

- You can add the tarp and gravel right away. Avoid using the swings for a couple days after the cement is poured.

- Q:How to install cement backer board in a shower?

- Install like drywall except use backer board screws. You can seal the joints. If going over a sub-floor you can use an adhesive between the sub-floor and the backer board.

- Q:What are the types of portland cement?

- their aren't any types, cement is cement. what your going to use it for determines what additives you mix in with it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

You Might Also Like