J55|N80 Slotted Liner

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Product Descriptions :J55|N80 Slotted Liner

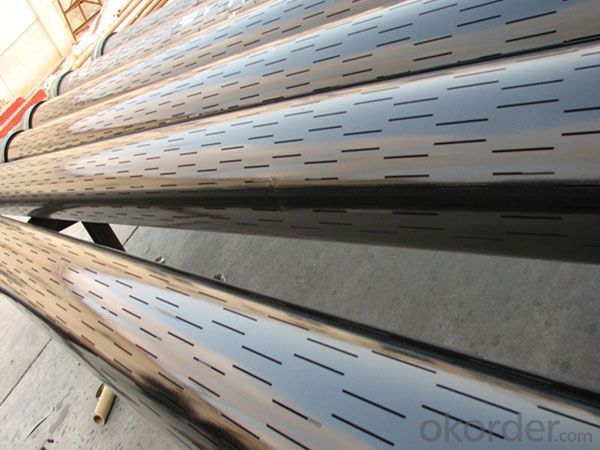

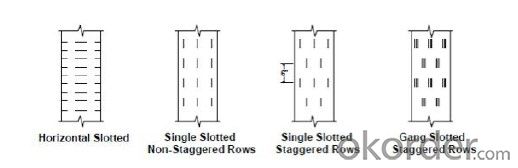

Slotted liners are used in gravel packed completions to prevent the production of gravel pack sand or can be used in stand-alone service when the formation grain size is large. Slot widths are often referred to in terms of "gage" or "gauge". Slot or screen gage is simply the width of the opening in inches multiplied by a 1,000. For instance, a 12 gage screen has openings of 0.012 inches. Slotted liners are manufactured by machining slot openings through oil-field tubulars with small rotary saws. Slotted liners are fabricated in a variety of patterns as illustrated in Figure.

The minimum slot widths that can be achieved is about 0.012 inches; however, slots widths cut below 0.030 inches in thickness involve higher costs because of excessive machine down time to replace broken saw blades that become overheated, warped and break. While the slotted liners are usually less costly than wire-wrapped screens, they have a smaller inflow area and experience higher pressure drops during production.

Slotted liners also plug more readily than screens and are used where well productivity is low and economics cannot support the use of screens. The single slot staggered pattern is generally preferred because a greater portion of the original strength of the pipe is preserved. The staggered pattern also gives a more uniform distribution of slots over the surface area of the pipe. The single slot staggered pattern is slotted with an even number of rows around the pipe with a typical 6 inch longitudinal spacing of slot rows.

SLOTTED LINER GEOMETRIES

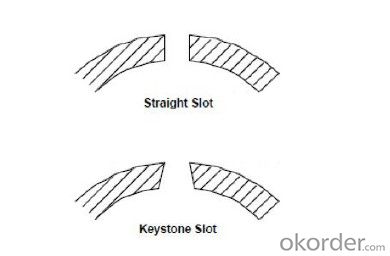

The slots can be straight or keystone shaped as illustrated in Figure. The keystone slot is narrower on the outside surface of the pipe than on the inside. Slots formed in this way have an inverted "V" cross-sectional area and are less prone to plugging since any particle passing through the slot at the OD of the pipe will continue to flow through rather than lodging within the slot.

STRAIGHT AND KEYSTONE SHAPED SLOTS

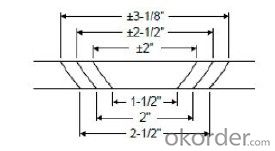

The length of the individual slots is gauged on the ID of the pipe. Usual practice dictates 1½ inch long slots for slot widths 0.030" and under, 2 inch long slots for slot widths between 0.030 to 0.060 inches and 2½ inch long slots for slot widths 0.060 inches and larger (see Figure 6.4). Slot width tolerance is generally 0.003 inches for widths 0.040 inches and wider and 0.002 inches for widths less than 0.040 inches.

STANDARD SLOT LENGTHS

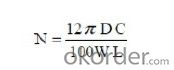

Slotted liners are generally designed to have a 3 percent open area relative to the OD surface area of the pipe although open areas up to 6 percent are feasible in some cases. The number of slots per foot required to achieve a given open area is calculated with the equation below.

where: N = required slots/foot (if N < 32, round up to the nearest multiple of four, if N > 32, round up to the nearest multiple of 8) Pie = constant (3.1416) D = outer diameter of pipe (inches) C = required open area (percent) W = slot width (inches) L = length of slot measured on ID of pipe (inches)

Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

- Q:How long are the seamless tubes? Are they six meters long?

- The production process of seamless steel tube in general can be divided into two kinds of hot rolling and cold drawing, cold-rolled seamless steel pipe production process than hot-rolled seamless steel pipe seamless pipe hot rolling to complex, diameter is generally greater than 32mm, thickness 2.5-200mm, cold-rolled seamless steel pipe outside diameter 6mm, wall thickness to 0.25mm cold rolling hot rolling high precision ratio.

- Q:Seamless steel pipe 8162 and 8163 what is the difference?

- GB 8162 is the structure of the tube, there is no need for flaw detection, the use of mechanical processing, stents;

- Q:What is ND steel pipe?

- ND steel also has the ability to resist chloride ion corrosion. ND steel pipe, the main reference indicators (70 degrees Celsius, 50%H2SO4 solution immersion 24 hours), and carbon steel, Japan imported similar steel, stainless steel corrosion resistance compared to higher than these steel grades. Products by domestic refineries and manufacturing units after the use of widely acclaimed, and achieved good results.

- Q:Seamless steel pipe and welded pipe what is the difference?

- The welded pipe is made directly from the stainless steel band by machine, and it is made of round steel or perforated by Guan Pi

- Q:What is lined pipe?

- Is the coating of the inside of the pipe, such as pipe conveying sulfuric acid will corrode, corrosion, but soft plastic pipe, buried in the ground to wall thicker, then you can use the liner and characteristics of hard for using steel pipe laying, sheathed in the steel pipe into the thin plastic tube, it can transport the sulfuric acid,

- Q:Why should the weak electricity be pre buried with galvanized steel pipe?

- Galvanized steel is widely used in construction, machinery, coal, chemical industry, railway vehicles, automobile industry, highway, bridge, container, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery and other manufacturing industries.

- Q:What is the outer diameter and wall thickness of DN40 steel pipe?

- DN40, refers to the diameter of 40mm, that is, an inch and a half, there are welded pipe and galvanized pipe,Ordinary wall thickness 3.5mm wt 3.84kg/mThicken 4.25mm weight 4.58kg/m

- Q:Is the seamless steel pipe used in the market hot or cold drawn?

- Small and medium-sized cold drawn and hot-rolled are many, large caliber is hot rolling, cold rolled spot less.

- Q:How can galvanized steel tubes be painted on the surface?

- Galvanized parts are nonferrous metals, ferrous metals are black, all metal adhesion is poor;

- Q:What does the diameter of a steel pipe project mean?

- Suppose we specify a standard that defines the nominal diameter of the same steel tube as G-1, then this G-1 is the same as DN50.I hope it doesn't make you any more confused, huh?. If you still don't understand, keep in mind that the nominal diameter is neither outside nor inside diameter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Hot Searches

Related keywords

You Might Also Like