Melt-extracted Stainless Steel Fiber Used in Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Quick Details

Place of Origin: China

Model Number: 304,310,430,446

Material: Stainless Steel, Stainless Steel

Feature: High quality grade

Standard: ASTM A820

Types: Melt Extracted

Length: 25mm/35mm/19mm

Diameter: 0.3mm-0.7mm

Melting Point: Greater than 1500C

Application: Refractory Industry

Package: In cartons then put into pallets.

Production process:

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check the pictures:

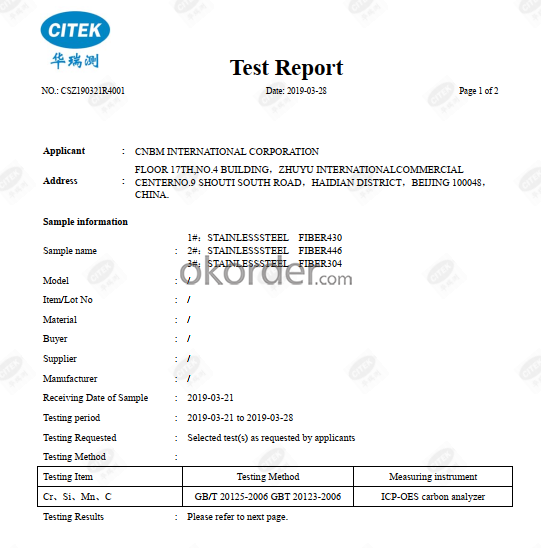

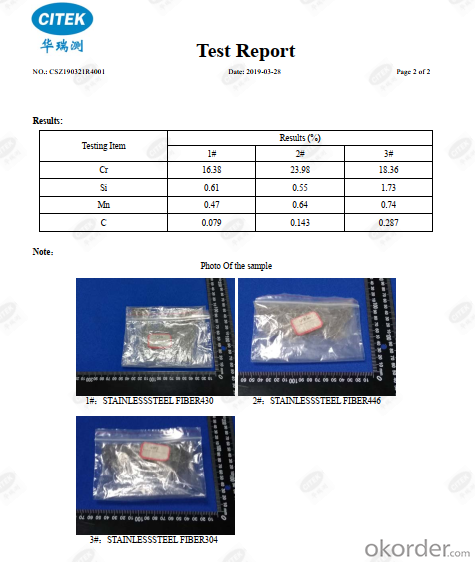

Test Report:

- Q:Do you know the refractories?

- Definition of refractory: inorganic non-metallic material with fire resistance greater than 1580 degrees is refractory.Refractory material is a part of material industry. It is named refractory material for thermal kiln. Refractory materials are divided into conventional refractory materials and special refractory materials, and conventional refractory materials are used in metallurgical furnaces, cement kilns, glass kilns and other thermal furnace lining materials, mostly processed from natural raw materials. Special refractory materials are of high purity, mostly oxide synthetic materials, used in special smelting equipment, or special parts of kilns.

- Q:What's the refractoriness and how to measure the refractoriness?

- Bottom each side length is 8 mm and upper side length is 2 mm. Under a certain temperature-rising speed, when heating, refractory's resistance to high temperature from melting is called refractoriness. The properties of cross section into an equilateral triangle and height is 30 mm. When it bends down until the vertex and chassis contact temperature is the refractoriness of sample. It bends due to the influence of its weight. Make the will-measured material into standard pyrometric cone.

- Q:Development trend of refractories

- Facing the survival and development of refractory industry challenges in many aspects, serious: 1, the user industry due to the progress of science and Technology (such as iron, iron and steel industry in the direct reduction furnace, to reduce casting, slag splashing etc.), reduce refractory material consumption; 2, refractory material environmental protection and ecological requirements; 3, users of the product quality and cost requirements; 4, users risk transfer, refractory material, the design requirements of the liner construction, maintenance services, and even provide construction equipment; 5, between refractory enterprises and personnel dispute price; 6, due to the industry downturn in some countries, the decline in refractory material and the lack of education, lack of young professionals; 7, resource depletion and other raw materials.

- Q:The fire prevention board line is made of what material?

- Crural line: wooden, in the market, there are sjoiner woodblock, peach wood and artificial engraving. The second classification is stone and the most used one is the marble graved or ceramics well-made one is taken as the first choise. Its price is a little bit expensive than the wooden one, but also a suitable choise. Condole supports: It has various category. The general furniture choose plaster and anti-firing plate and the other also have a choice of steel. You can make a suitable choice according to the need. If it is contracting project, it depends on your project specific plan and funds plan. In a word, beauty and harmony should be given priority since it is the source of design.

- Q:Who knows the new fireproof and thermal inuslation matertial?

- New fireproof and thermal inuslation matertial: foam concrete building blocks brick. The foam concrete building blocks brick is a new fireproof and thermal insulation material, with distinct advantages compared with the organic insulation material . Foam concrete can be used as wall materials, and it has a good self-insulation properties, so there is no problem of dropping off the outer insulating layer. A small part takes external wall exterior insulation, with mostly anchoring or dry hanging, which are not easy to fall off. Very few uses paste. Since the foam concrete and wall materials are of the same nature and strong adhesive, so it is also not easy to fall off.

- Q:Who knows about roof fireproofing materials?

- At present, only phenolic foam boards can meet requirements. The test temperature can be 2,000 degrees, and there is no molten droplet during the tests and it can maintain integrity. heat conductivity coefficient: 0.03W / (mk), non-combustible, non-toxic, smokeless!

- Q:How to count the construction costs of refractories?

- In winter, the temperature of the the fire-resistant masonry, fire-resistant plastic, sodium silicate, phosphoric?acid castable should be maintained above 5 ℃. Usually greenhouses in which heating facilities are installed to maintain the appropriate temperaturere for the construction environment should be erected in refractory masonry. The temperature around the construction site of the industrial furnace and refractory masonry shall not be lower than 5 ℃.

- Q:What are the differences between first-level fire-resistant materials and second-level fire-resistant materials?

- 1, these refer to fire resistance rating of building materials. 2, As for steel, elements that used in different parts should reach different duration of fire resistance according to fire resistance rating. For example, fire resistant pillars of first level can endure fire within 3 hours; the second level, 2.5 hours; the third level, 2 hours. With respect to beams, three levels of fire resistance are included.

- Q:On the problem of making refractory materials

- Refractories mainly depend on their high melting point characteristics. The refractory market is mainly Magnesium Oxide material.

- Q:What are the refractory materials above 1000℃

- I have no idea what field you are in, and I am skillful at making refractory materials, because this is my job. You can send me an email informing your purpose, here is my email address .

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Related keywords

You Might Also Like