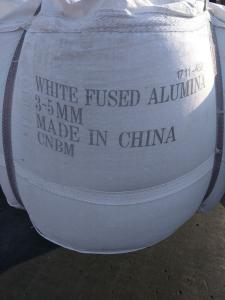

REFRACTORY WHITE FUSED ALUMINA WITH LOW IRON

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Quick Details

· Place of Origin: Henan, China

· Shape: Powder or Grain size

· Material: Alumina

· Al2O3:99%min

· SiO2:0.1%max

· Fe2O3:0.1%max

· NA2O:0.35%max

· Refractoriness (Degree):1770°< Refractoriness< 2000°

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy and Refractory

· Product name: White Fused Alumina

· Color: White

· Size:0-1mm/1-3mm/3-5mm/-200mesh/-325mesh

· Certificate:ISO9001

· Usage:Fire Resistance Place

· Type:Raw Refractory

· Packaging Details:Bags/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, you only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check our other products in website.

- Q:how is the high-temperature flame-retardant fibre board?

- high-temperature flame-retardant fibre board is good decorative material. Hope it helps you.

- Q:What's the fireproof specification for constrcution external wall thermal insulation materials?

- incombustible material: Class A1 (homogenous): such as YT inorganic active insulation material for wall thermal, foam glass, rock(ORE) wool, glass wool, insulation?board of aerogel,expanded perlite series, expaned glazed hollow bead, foam insulation boards, ETC. Class A2 (non-homogeneous composite): such as phenolic foam, gelatine powder polyphenyl granule thermal insulation material, inorganic coating materials and other nonflammable material. phenolic foam insulation board, urea resin foam and board, high flame-retardant polyurethane rigid foam and board, high flame retardant polystyrene cystosepiment, gelatine powder polyphenyl granule heat insulating slurry and other combustible?materials. Requirements for combustion levels of common antiflaming EPS, common inflaming retarding XPS, common antiflaming rigid PU foam board: Class A is incombustible?material (product); B1 nonflammable material (product); B2 combustible?material (product); B3 combustible material (product).

- Q:How many kilns using refractories are needed? What are the furnaces respectively?

- Kiln and five hundred-degree centigrade thermal equipment need to use refractories, glass furnaces, electric arc furnaces, mixer, cement rotary kiln, open hearth furnace and limestone kiln; in fact, when the temperature is more than four, the mesh belt furnace, blast furnace, cupola oven, stove, pushing plate kiln, furnace, heat treatment furnace, roller kiln, down draft kiln, ladle, coke, shuttle kiln,etc.

- Q:What's the B grade fireproofing material?

- Grade B: rubber and plastic, extrusion molding, polyphenyl, PEF. organics, extruded sheet, polyphenyl board, phenolic resin. Hairong modules (thermal insulating and fireproof material) can reach grade B1 in fireproof performance.

- Q:How can refractory material of the electric furnace be used for longer.

- Minimize mechanical shock, Electrical furnace commonly referred to must be electrical arc furance. The wall of electric arc furnace should be constrcuted with magnesite carbon brick. Its hearth permanent layer should be constrcuted with mansornary magnesia brick. High alumina brick is usually used to aviod furnace cover suddenly get hot and cold. But its service life is lower. At present integral casting furnace cover is made of alumina magnesia. Terminal will be created even without the use of refractory material. Consumption is much faster if using refractories material or whole knottiing mainly.

- Q:What are the materials used in refractory material processing?

- Refractory materials generally refer to inorganic non-metallic materials with a refractoriness of more than 1580 degrees. It includes natural ore and a variety of products made by a certain process according to certain requirements. It has certain high temperature mechanical properties and good volume stability. It is the necessary material for all kinds of high temperature equipment. Ordinary refractories are often used brick, semisilica brick, clay brick, high alumina brick, magnesia brick etc..

- Q:What refractory material lead smelting furnace needs?

- Q:What is the fire resistance thickness of the thin fire-retardant coatings?

- There is no detailed requirement on the thickness of the thin steelwork fireproof coatings in the "Code for application technology of steelwork fireproof coating", and the thickness there refers to a certain thickness which must(at least) have fire resistance for a certain time. The thickness of fireproof coatings in engineering generally depends on the manufacturer's test reports. Our thin steelwork fireproof coatings: the fire resistance is 2.5 hours, the thickness is 4.9 mm, the fire resistance is 2.0 hours, the thickness is 3.5 mm, the fire resistance is 1.5 hours, the thickness is 1.75 mm, the fire resistance is 1.0 hours, the thickness is 1.17 mm.

- Q:Does anyone know which materials belong to light fire resistant material?

- Fire partitions can be divided into organic and inorganic fire partitions, the main ingredient of organic fire partitions is organic material, which can be used for cable tray with corrosion-resistant and fire protection requirements, and the main ingredient of inorganic fire partitions is inorganic material, mainly used for fire protection. As the main component is inorganic material, it can not be use in projects with acid-resistant and alkali-resistant requirements. Of course, the price of the same amount of organic fire partitions is generally more expensive than that of the inorganic fire partitions . The fire endurance of these two products of general enterprises are 3 hours.

- Q:What are the fire protection standards of insulation materials?

- According to the three versions of GB8624 (1997,2006,2011), the fire rating of external walls can be basically divided into: A1-, A2-, B1-, B2-, B3-level. The detailed divisions are determined by many technical indicators. It is a very professional and technical long story. Please contact QINGDAO SHANFANG INSTRUMENT CO., LTD for detail information, they are specialized in manufacturing fire rating testing instruments of external walls.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Related keywords

You Might Also Like