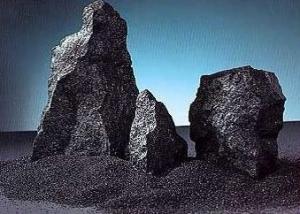

TILTING BROWN FUSED ALUMINA IN REFRACTORY USE WITH SIO2:1.3

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Quick Details

· Place of Origin: Henan, China

· Shape: Block or grain size or powder

· Material: Alumina

· Al2O3:95%min

· SiO2:1.3%max

· TiO2: 3%max

· Fe2O3:0.3%max

· CAO:0.6%max

· MGO:0.3%max

· K2O+Na2O:0.3%max

· B.D:3.8g/cm3min

· MOI:0.2%max

· Refractoriness (Degree):1770°< Refractoriness< 2000°

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy and Refractory

· Product name: Brown Fused Alumina

· Color: Brown

· Size:50MESH/100MESH/200MESH/325MESH/0-1MM/1-3MM/3-5MM/0-40MM

· BULK DENSITY:3.8g/cm3min

· Certificate:ISO9001

· Usage:Fire Resistance Place

· Type:Raw Refractory

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, you only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check our other products in website.

- Q:Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q:What is the role of adding chromium oxide green in unshaped refractory materials

- Generally, less is added in corundum or corundum spinel refractory material, but it can significantly improve the material performance such as high temperature strength, erosion resistance, thermal and shock stability, etc.

- Q:What is the upper temperature limit for refractory materials?

- Different materials are different. In the professional field, there is a triangulation cone softening point experiment as a reference for using the upper temperature limit.

- Q:what's the standard of fireproofing material?

- Class A1 is divided according to the combustion performance of GB8624-2006 building materials and products. Specific technical index requirements are: 1, the temperature rise ≤30 degrees;mass loss rate ≤50%; combustion duration time is 0; 2, main components, overall products, gross calorific value of external secondary components ≤2.0MJ/kg; any inner secondary component ≤1.4MJ/kg; (there are difference between homogeneous and non-homogeneous). Z802 building materials noninflammability testing furnace has to be used for testing technical indicators mentioned in test 1, using Z805 building materials combustion heat value to test technical indicators mentioned in test device 2.

- Q:Why the corundum can be used as refractory

- Because the main component of corundum is aluminum oxide!

- Q:What is the criterion of entry of refractory clay industry?

- Standard sizes of refractory bricks in our country are: 230mm × 114mm × 65mm; ordinary brick: 240 * 115 * 53, Building blocks: (blind holes, through-holes) 240 * 390 * 190 * 190,240 * 190,240 * 190,190 * 90 * 190 * 390 * 190,190 * 190,190 * 190,190 * 190 * 90 * 190, 140 * 390 * 190,140 * 190,990 * 190 * 200 * 400, from 0 * 390 * 190 * 190,90 * 190,90 * 90 * 190. There is also an interlocked hollow blocks: 90 * 200 * 200 * 400,90 * 245,90 * 200,90 * 200 * 200 * 100, 90 * 200 * 290,150 * 275,150 * 200 * 200 * 200, 150 * 200 * 100, 150 * 200 * 290.

- Q:What kind of refractory materials are used in metallurgy industry?

- Argon-blowing rod, siliceous dry vibrating materials, desulfurizer, slag-stopping ball, stainless steel thermal insulating agent with high efficiency, dry vibration material, sizing nozzle heat-insulating panel, chrome refractory , refractory carstables for ladles, magnesia carbon refractory, package castable, siliceous drainage agent, tundish block, iron trough, deoxidizer, compound deoxidizer,silicon manganese alloy , stemming, floating plug,slagging agent. The main materials are as follows: recarburizer, covering agent, intermediate frequency furnace burden, mould fluxes, insulation thin slag agent, skimmer repair material, joint sealant.

- Q:It the Special Fire-Proof Material belonged to ceramics? Is there a national standard of the Special Fire-Proof Material?

- The fiber and reinforcing material of the metal ceramic is also belonged to the Special Fire-Proof Material. ~~~~GB is too much trouble, GB online should ~~~ Lei Bao Refractories for you. The high temperature inorganic coating. 5. The refractory compound. 3. The high melting point oxide. You can search it on the internet according to the classification~~~~ The special refractories can be divided into five categories: 1. metal ceramic

- Q:Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will be completely liquefied in the furnace of about 1100 degrees for half an hour and will not deform below 600 degrees. toughened glass fire-resistant glass is the product of ordinary glass after being processed Glass will mainly burst after encountering fire. When unevenly heated or encountering sudden drastic changes in temperature, ordinary glass will burst if the sharp temperature difference is over 70-120 degrees and toughened glass will burst at 200 degrees. It is not yet clear of the bursting temperature for the refractory glass. (I hope this answer can help you!) Hope you adopt !)

- Q:What are the refractory materials above 1000℃

- corundum would be fine

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Related keywords

You Might Also Like